Tool reconditioning

The cross-industry pressure to optimise costs makes professional tool reconditioning a decisive factor in maintaining profitability. Especially in the production of machining-intensive parts and components, tools made of solid carbide are indispensable and represent a significant cost factor.

When using conventional reconditioning processes, often only a part of the performance of the new tool can be restored. In some cases, the tool life is significantly reduced. When planning production, due attention must be paid to the tool life of tools that are regrinded several times – so as to ensure the best machining quality.

Thanks to precise reconditioning, state-of-the-art de-coating and coating processes – plus our specially developed micro finish polishing process – we can restore the performance and tool life of your tools to 100%. Our innovative reconditioning process lets us calculate costs on a radically new basis – paving the way for our customers to save massive amounts of money.

- Tool-friendly de-coating without cobalt leaching

- Precise regrinding for optimum performance

- Smooth coating surfaces and optimum layer adhesion thanks to Quad-Coating

- Perfectly polished tools using the micro finishing process

Regrinding

End Mill

of solid carbide and HSS

Ø = 2 - 80 mm

- incl. 1st / 2nd Clearance angle or eccentric back grinding

- different helix

- unequal distribution of teeth

Solid carbide high performance end mill

Especially for the hard milling

Ø = 3 - 25 mm

Teeth = 4 - 10

Solid carbide ball nose end mill / torus

end mill for hard milling

Ø = 2 - 20 mm

Teeth = 2- 4

- Toleranz of radius: ± 0,01 mm

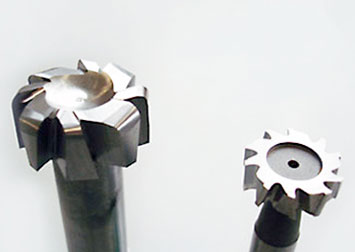

Typing Router and Face Milling Cutter

HSS and solid carbide (tipped with carbide)

Until Ø 250 mm

Prism cutter, Angle cutter

HSS and solid carbide (tipped with carbide)

- Prism cutter

- Dovetail Cutter

- T-slot cutter

- Quarter circle milling cutter

Flat countersink, Countersink

HSS and solid carbide (tipped with carbide)

- Flat countersink

- Countersink

Hob Cutter

Solid carbide and HSS, straight fluted

- Hob Cutter until diameter 100 mm, length 200 mm

- Cutting wheel

Drills

Carbide metal and HSS, twisted and straight fluted

- sc drills of all leading manufacturers

- four-chamfered drill

- drilling heads

Deep hole drill

Solid carbide

- Until Ø 32 mm and length = 2000 mm

- with corner radius or ball nose

Tap tools

Solid carbide and HSS

- Tap beginning with M8

- Thread milling cutter

- Threading die

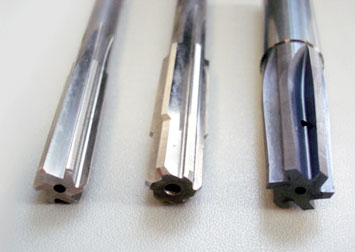

Reamer

Solid carbide and HSS, straight fluted and twisted

- Step reamers

- Taper reamers

- Interchangeable head until Ø 100 mm

Indexable Inserts

Solid carbide

- DIN-Inserts

- Special and profile inserts

- Milling head

Saw blades

HSS and solid carbide

- HSS saw blades until Ø 450 mm

- Solid carbide saw blades until Ø 200 mm

Knife Blade

HSS and solid carbide

- Top knife until Ø 200 mm

- Under knife until Ø 200 mm

- Crush until Ø 350 mm

Modification

Flat countersink:

Profile grinding

Changing of diameter

Dovetail Cutter:

Changing of angle

Countersink:

Changing of cone angle

Quarter circle milling cutter:

Changing of radius

Reamer:

Changing of lead angle

NC spot drill:

Changing of point angle

Tap:

Changing of lead length

T-slot cutter:

Add a corner radius

Slot cutter:

Changing of diameter and width